The ropes are the strongest part of the pilot ladder. Since the rope material is manila rope, it is very vulnerable and sensitive to salt and water. Special care should therefore be taken when stowing the pilot ladder during the sea voyage.

As per ISO 799 the following requirements apply to the side ropes:

- Manilla rope as per ISO 1181:2004 or similar

- Rope’s breaking strength is 24 KN, with a diameter of 20 mm.

- Metals used for clamping and fastening shall be corrosion resistant

- The side ropes are continuous loops with the joint above the top step or below the bottom step only.

- When the ladder is in use, the ropes cannot come in contact with the ship’s hull.

The ropes are the strongest parts of the pilot ladder, rated at 24 kN each.

There are 2 double side ropes on each side of the ladder. That makes the total strength 2 x 48 kN. The ropes should be the only part of the ladder to carry the static and dynamic weight of the ladder. These forces should never be transferred to the ship’s deck via wooden parts of the ladder, or uncertified strong points on deck, such as railings and pipes. That’s why shackles and tongues on deck should not be used to secure the pilot ladder. Use only designated strong points !

The soft material of which the ropes are made requires soft edges in way of the pilot access point over which the pilot ladder is hanging overboard. Once again, this both to enhance safety as well as the ladder’s lifespan.

A comparison: Manila Rope vs. Sisal Rope for Pilotladder Ropes

Herman Broers 2 mins ago

Introduction

When it comes to producing pilotladder ropes, selecting the right material is crucial to ensure strength, durability, and safety. The most popular choice is Manila rope, which is also prescribed for use in ISO 799:2019. There are also pilotladders made from sisal rope on the market, which obviously does not meet the requirements of ISO 799. This article aims to delve into the differences between Manila rope and Sisal rope, taking into consideration ISO Standard 799, which prescribes a minimum breaking strength of 24 kN and a diameter of 20mm for Manila rope.

Manila Rope

Manila rope, also known as hemp rope, is a natural fiber rope made from the abaca plant, which is native to the Philippines. It has been widely used for centuries due to its exceptional strength and resistance to UV radiation, saltwater, and harsh weather conditions. The ISO Standard 799’s prescription of Manila rope for pilotladder ropes stems from its robust properties.

Manila rope’s breaking strength is determined by its construction, diameter, and quality. As per the ISO Standard 799, a minimum breaking strength of 24 kN is mandated for pilotladder ropes. Manila rope typically meets or exceeds this requirement, ensuring adequate safety during ladder climbing operations.

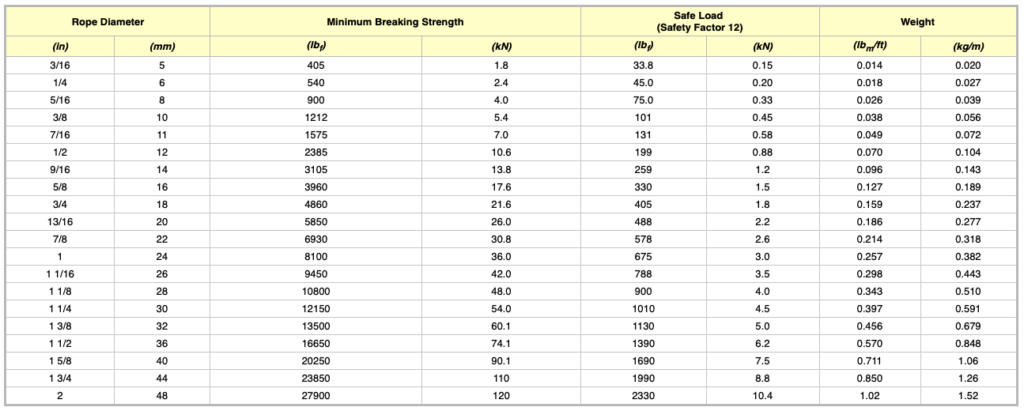

As per figure 1, the minimum breaking strength of a 20mm manila rope is 26 kN, which meets the required Minimum breaking strength as per ISO 799:2019 (24 kN)

One of the key advantages of Manila rope is its durability. It possesses excellent resistance to abrasion, making it suitable for heavy-duty applications like pilotladder ropes. Manila rope can withstand repeated use and exposure to various environmental conditions, thus ensuring its longevity over time.

Manila rope offers good handling characteristics (“Knotability”), allowing for easy manipulation and secure knotting. This is essential for the safe rigging of ladder ropes, as a properly tied and secure knot is vital for the safety of pilots. The natural grip of the Manila rope also contributes to enhanced ladder stability during ascents and descents.

Sisal Rope

Sisal rope is derived from the Agave sisalana plant, primarily cultivated in tropical regions around the world. It is recognized for its strength and durability, but it exhibits some differences compared to Manila rope. While the ISO Standard 799 prescribes Manila rope for pilotladder ropes, it does not specifically mention Sisal rope.

Sisal rope possesses commendable durability and can withstand moderate exposure to environmental factors. However, it is generally less resistant to moisture, UV radiation, and saltwater when compared to Manila rope. Therefore, proper care and regular maintenance are essential to ensure the longevity of Sisal rope.

Furthermore, Sisal rope has a coarse texture, which can make it more challenging to handle and knot compared to Manila rope. While it could still be effectively used for ladder ropes, users must pay extra attention to secure and tight knots to guarantee the safety of pilots.

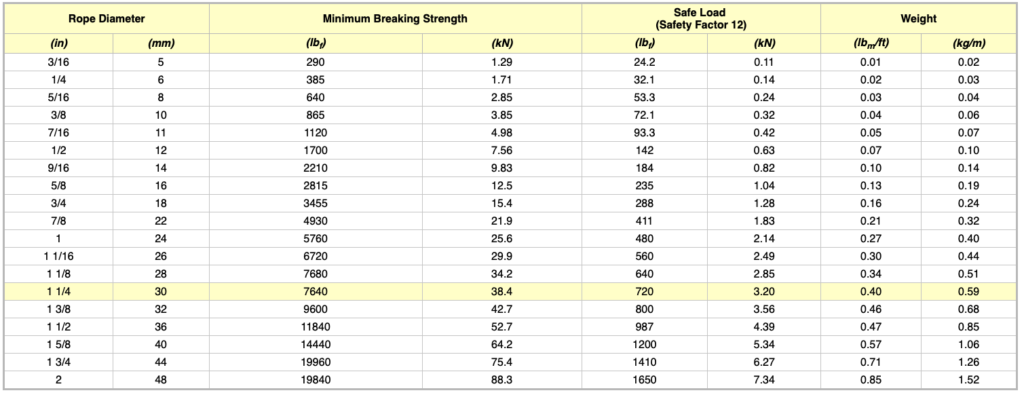

In figure 2 the minimum breaking strength (MBS) of Sisal is given. From this table it can be concluded that Sisal’s MBS is 70% compared to the MBS of manila rope. Futhermore the MBS of 24 kN for 20mm rope cannot be met.

Conclusion

Manila rope, specifically prescribed in ISO Standard 799, guarantees a minimum breaking strength in excess of the required 24 kN, ensuring optimal safety during ladder climbing operations. The cost of manila rope is roughly about 15% higher than sisal. The fact that manila rope offers much better strength, handling, resistance and longevity properties makes it the obvious choice for the use in pilotladder production. Do not accept anything less!

QUIZ: TEST YOUR KNOWLEDGE ABOUT THIS SECTION OF THE WEBSITE (CLICK HERE)

IMO 1045(27) Pilot Transfer Arrangements:

2.2 Ropes

2.2.1 The side ropes of the pilot ladder should consist of two uncovered ropes not less than 18 mm in diameter on each side and should be continuous, with no joints and have a breaking strength of at least 24 Kilo Newtons per side rope. The two side ropes should each consist of one continuous length of rope, the midpoint half-length being located on a thimble large enough to accommodate at least two passes of side rope.2

2.2.2 Side ropes should be made of manila or other material of equivalent strength, durability, elongation characteristics and grip which has been protected against actinic degradation and is satisfactory to the Administration.

2.2.3 Each pair of side ropes should be secured together both above and below each step with a mechanical clamping device properly designed for this purpose, or seizing method with step fixtures (chocks or widgets), which holds each step level when the ladder is hanging freely. The preferred method is seizing.1

1Refer to the recommendations by the International Organization for Standardization, in particular publication ISO 799:2004, Ships and marine technology — Pilot ladders, part 4.3a and part 3, paragraph 3.2.1.