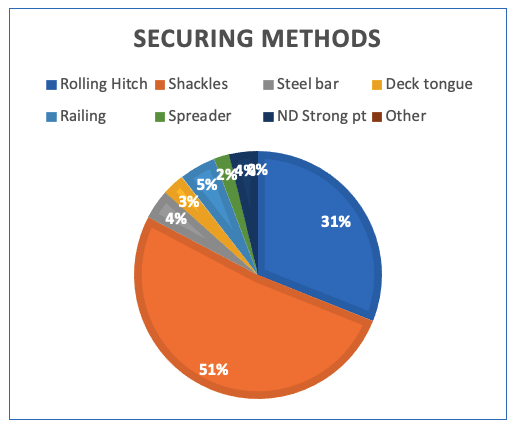

In december 2020, research was conducted into the securing methods of pilot ladders at intermediate length. Using an online survey, 486 observations have been received from pilots around the world, the majority of which came from Europe (78%).

Conclusions:

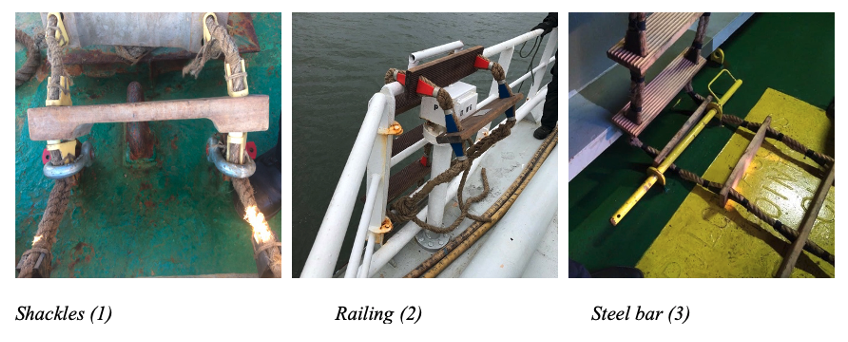

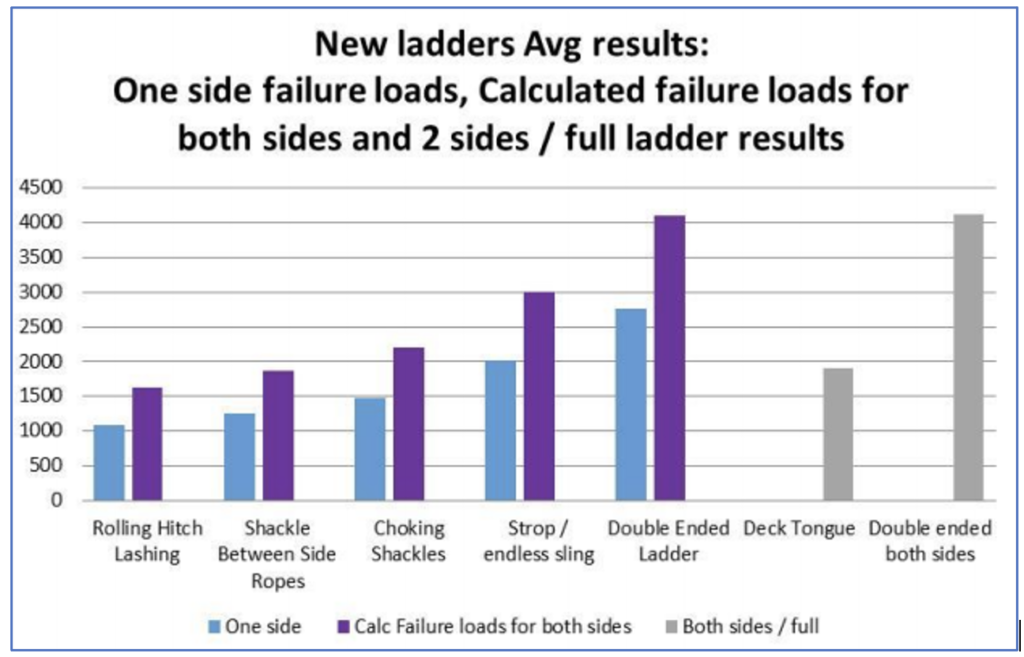

It has been shown that a majority (51%) of pilot ladders is secured by means of D-shackles, when secured at intermediate length. Previous research (Evans, 2020) has proven that this method has only about 50% of the strength of the pilot ladder when secured at full length (“double ended ladder”), or by means of the “endless-sling” method.

Rolling Hitch Knot (7)

The rolling hitch knot is used in 31% of the observations. When used correctly, this method is rated at only 39% of the strength of the ladder when secured at full length (“double ended ladder”), or by means of the “endless-sling” method.

There is no correlation between ship’s types or geographical area and the securing methods in use. In other words, all identified methods are in use on all types of ships, worldwide.

The use of D-shackles as a securing method is a very easy, user-friendly securing method for the ship’s crew. Also, many ships have been specifically designed to facilitate this method.

The use of a rolling hitch knot is the most used alternative to the D-shackle. The frequent use of this method is probably caused by the fact that it is being promoted by pilots around the world, in publications and on social media. It is considered the least harmful method of securing to the integrity of the pilot ladder.

From the survey, no relationship could be established between securing method and ship type or securing method and geographical area. In other words, all securing methods are in use on every ship type, worldwide.

Discussion

The two most frequently used methods of securing pilots at intermediate length are either demonstrably weaker than the total strength of the pilot ladder or are considered harmful to the integrity of the pilot ladder itself. There is no legislation or standard of a securing method which is both of equal strength of the ladder, and harmless for the ladder’s structural integrity.

Without accident statistics it is hard to describe the present-day practice of securing pilot ladders at intermediate length as “unsafe”. This research however shows that the most used methods of securing are not the most effective with regards to strength and the integrity of the pilot ladder.

The nature of the embarkation and disembarkation is a critical process, meaning that serious injury or fatalities are the likely outcome as the result of accidents involving pilot ladders.

The fact that there is no proven design for the securing of a pilot ladder at intermediate length in a safe, convenient manner calls for innovative solutions to the ever-present danger of breaking of failing pilot ladders.

Recommendations:

This report should serve as a reminder to maritime pilots, legislator and other stakeholders in the maritime industry that an industry wide problem exists: the regulatory gap regarding pilot ladders which are secured at intermediate length. Much work needs to be done to improve this situation.

- The research conducted in this survey should be repeated regularly to identify trends and changes in the securing methods used for pilot ladders at intermediate length. IMPA could play an important role if they are willing to incorporate this research into their annual safety survey.

- A new innovative securing method for pilot ladders at intermediate length should be developed, Ideally, this process should involve ship designers, ship owners, pilot ladder manufacturers as well as maritime pilots. The design of the pilot ladder itself must be subject for reconsideration if needed.

- An industry standard should be developed regarding the securing of pilot ladders at intermediate length, involving all relevant stakeholders in the maritime industry.

- A global database on pilot ladder incidents, accidents and near-miss database should be developed in order to generate much needed management information which can be used to improve safety of pilot ladders in general.

Afterword

I want to thank all maritime pilots from around the world who have contributed to this survey by sending in their observations. Also, all colleagues who work tirelessly to improve pilot ladders safety on a daily basis should be commended.

If you have any questions on this subject, or want more information on this survey , please contact me on info@pilotladdersafety.com

Stay Safe,

Herman Broers

Click on the link below to download the full report.