A bad pilot ladder, with worn-out steps and side ropes is not a good welcome sign for a pilot onboard a ship. It is easy to inspect the steps every time the ladder is used. Make sure the steps are in good shape, and clean, ready to use.

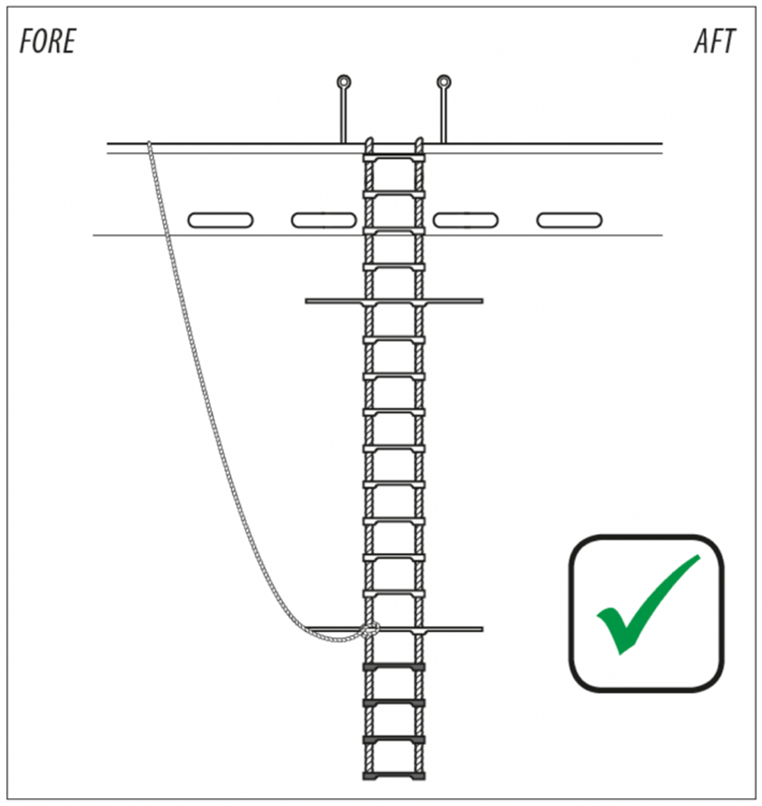

The retrieval line is sometimes referred to by pilot as “the trip line”. On a rolling ship it can easily get in the way of the pilot boat fendering or crew, or the pilot climbing the ladder. And there is only one way it should be attached: At or above the bottom spreader, leading forward. This also implies that when a combination ladder is used, the retrieval line of the pilot ladder should be rigged underneath the accommodation ladder.

Retrieval line: At or above the bottom spreader, leading forward.

When markings are used, they should not be painted on the ladder’s steps, paint and varnish make the ladder slippery and therefore dangerous.

As per ISO 799, the following requirements apply to the steps:

- Steps to be made from hardwood, resilient plastic or rubber

- If made of wood, they are free of knots and uncoated

- Steps have a grooved, patterned , or moulded non-skid surface

- Anti skid adhesive sheeting may not be used

- Step thickness should be a minimum of 25 mm ( excluding the non skid treatment or grooving)

- The lower four steps shall be made of rubber

- The fifth step from the bottom shall be a spreader, and from there every 3 meters a spreader shall be fitted, minimum 1.8 m length.

- Replacement steps shall be provided by the manufacturer only

- No more than 2 replacement steps can be used

A message from pilots to bosuns worldwide:

“Please don’t cover the loose ends of the pilot ladder with electrical tape or duct tape! This traps moisture, keeping the ropes wet and causing them to rot much faster.”

IMO 1045(27) Pilot Transfer Arrangements

2.1.2 The steps of the pilot ladders should comply with the following requirements:

- if made of hardwood, they should be made in one piece, free of knots;

- if made of material other than hardwood, they should be of equivalent strength, stiffness and durability to the satisfaction of the Administration;

- the four lowest steps may be of rubber of sufficient strength and stiffness or other material to the satisfaction of the Administration;

- they should have an efficient non-slip surface;

- they should be not less than 400 mm between the side ropes, 115 mm wide and 25 mm in depth, excluding any non-slip device or grooving;

- they should be equally spaced not less than 310 mm or more than 350 mm apart; and

- they should be secured in such a manner that each will remain horizontal.

2.1.3 No pilot ladder should have more than two replacement steps which are secured in position by a method different from that used in the original construction of the ladder, and any steps so secured should be replaced as soon as reasonably practicable by steps secured in position by the method used in the original construction of the pilot ladder. When any replacement step is secured to the side ropes of the pilot ladder by means of grooves in the sides of the step, such grooves should be in the longer sides of the step.

2.1.4 Pilot ladders with more than five steps should have spreader steps not less than 1.8 m long provided at such intervals as will prevent the pilot ladder from twisting. The lowest spreader step should be the fifth step from the bottom of the ladder and the interval between any spreader step and the next should not exceed nine steps.

2.1.5 When a retrieval line is considered necessary to ensure the safe rigging of a pilot ladder, the line should be fastened at or above the last spreader step and should lead forward. The retrieval line should not hinder the pilot nor obstruct the safe approach of the pilot boat.

2.1.6 A permanent marking should be provided at regular intervals (e.g. 1 m) throughout the length of the ladder consistent with ladder design, use and maintenance in order to facilitate the rigging of the ladder to the required height.