Properly securing the pilot ladder is one of the most critical aspects of pilot ladder safety. While there are many regulations in place, clear guidelines on how to secure a pilot ladder to the ship are often missing.

Since a pilot ladder cannot always be deployed at full length due to varying freeboard levels, it often needs to be secured at an intermediate length. To do this safely, the following principles must be followed:

- The ladder’s weight must never rest on its steps, spreaders, or chocks, as these are not designed to bear loads.

- The securing method must not compromise the ladder’s structural integrity.

- The pilot ladder should be secured to designated strong points on the ship’s deck, using the side ropes for support.

To ensure safety, the ladder’s weight must be transferred directly from the side ropes to the strong points on deck. Using the steps, spreaders, or chocks for this purpose is dangerous, as they are not built to support the load. Likewise, shackles, bars, or metal tongues should never be used, as they can damage the ladder and put strain on parts that are not designed to carry weight.

Best Practice for Securing a Pilot Ladder

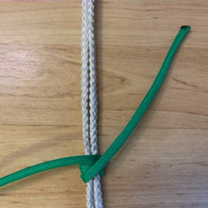

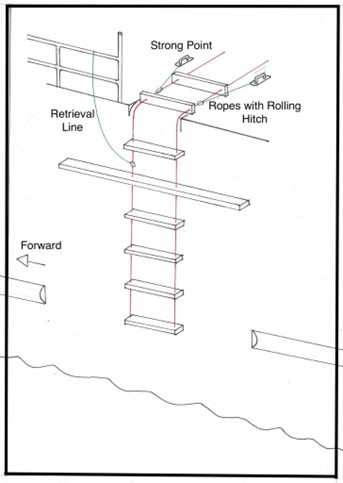

The safest and most effective way to secure a pilot ladder is by using two strong manila ropes, each with a minimum strength of 24 kN. These ropes should be attached directly to the side ropes of the pilot ladder using a rolling hitch knot (see diagram below). This method ensures the ladder’s weight is properly supported while preventing damage to the ladder itself.

By following these simple but essential steps, ships can ensure safer and more reliable pilot ladder operations.

The pilot ladder should be positioned over the deck edge, through an opening in the ship’s railing, or over a bulwark. If it is placed over a bulwark, a bulwark ladder must be used to ensure safe access. To prevent damage to the side ropes, it is best if the deck edge is rounded rather than sharp.

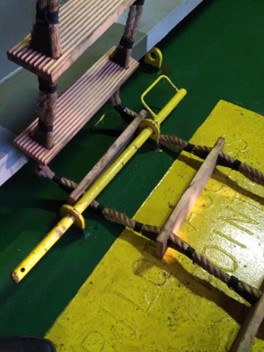

In the next picture, the pilot ladder has been rigged exactly as it should be. This setup ensures that the ladder’s weight is properly transferred to the deck and that there is no unnecessary wear from sharp edges or improper load distribution. In this case, the strong points have been certified for a safe working load of four tons—an excellent example of how it should be done!

The rolling hitch knot used on a well rigged pilot-ladder arrangement. Observe the marked strong points on deck (SWL 4T) Pic: Cpt. Gary Clay,

Always use a designated strong point to secure the ladder. Never use railings or pipelines since they have no certified strength.

Securing of the Pilot Ladder

There is plenty of room for improvement when it comes to designing a ship in a way that makes securing the pilot ladder easier.

In some cases, the layout of the pilot access area is so poorly designed that crew members are left with no choice but to secure the ladder to hand railings with sharp edges. This can cause serious damage and wear to the ladder’s ropes, reducing its safety and lifespan.

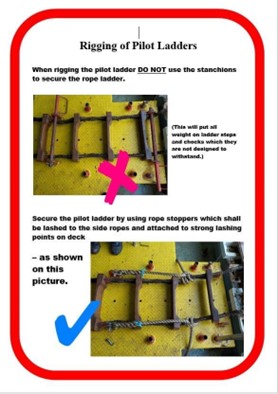

The poster below is a great example of clear and effective instructions. Displayed at the pilot boarding area on some Maersk vessels, it provides a simple and practical guide to securing a pilot ladder correctly, leaving no doubt about the right way to do it.

“Rigging of Pilot Ladders” Instruction found onboard of a Maersk vessel

In the next picture it is clear that the design of the pilot ladder access point sometimes does not allow for the required length of rope to secure the ladder, like in the previous case. There are two eyes, which are only inches away from the rounded edge and therefore useless. In this case, two designated eyes (strong points) should have been welded onto the main deck , preferably at a good distance from the ship’s side, well marked and load tested to at least 48 kN each, which is the total MBL ( Minimum Breaking Load ) of the side ropes.

Pilot access area without strong points for securing the ladder

The following pictures show four methods of intermediate securing of pilot ladders which are not recommended by pilots for various reasons. (see the description under each picture)

Deck Tongue: all weight rests on the steps

Steel Bar: damaging to the chocks and steps of the ladder

D-Schackles: damaging to the chocks and steps

The spreader as a securing device: it is not designed to carry the weight